What Is Packaging In The Logistics World?

Why is packaging so important in logistics? In recent years, the demand for distribution processing, which does many different things during shipping, has been on the rise. This makes distribution more valuable and makes it easier for people to get things. You might scratch or break products if you transport them by plane, ship, or truck in their raw state. The quality of the products might also go down. It’s the packaging that stops this.

Many businesses think that the way their products are packaged is a way to communicate with their customers, too. If you want to protect the item inside the packaging, you can use it as a marketing tool that tells you about the product and promotes it. The more attractive a package is, the more customers it draws in.

There are a lot of times when the words packaging and packing are used together. In simple terms, the packaging covers each unit of an item that the customer can buy. Packing is the covering or support for such products when transported or handled in bulk. These words sound the same and are very similar, but they are very different.

Packaging: Logistics Definition

Packing is the act of wrapping up a packaged good to protect the environment or the packaged well itself, to make it easier to portion the packaged good for production or use and to store and market it. The packaging is made up of packaging material and packaging tools, making it possible to package, seal, and prepare for shipping. Packaging is the result of a packaging process (see also (sorter) packing), which starts with the design of the packaging and ends when everything is put together. This whole process is called a packaging system.

The Definition:

Packaging is a way to ensure that goods are safe, secure, efficient, and effective when handled, transported, stored, sold, eaten, and recycled, reused, or thrown away. It also ensures that consumer value, sales, and profit are maximized.

People at the University of Lund named Mazen Saghir are studying the concept of packaging logistics.

We can break down the three main functions of packing or packaging into three parts:

- Logistics is all about making transportation easier, protecting goods and the environment, and making information (see also Information in Intralogistics). For example, RFID.

- When you market something, people will see it (format, design, customer loyalty, and satisfaction)

- There are a lot of different things that (recyclable, reusable, one-way, reverse logistics)

Packaging to protect products and quality assurance in logistics

In packaging logistics, many new problems are coming up because of the rise in online shopping. It used to be that B2C habits (the customer’s desire for “faster, closer, better”) were only for B2B supplier-client relationships. From a B2C customer’s point of view, the most important thing is the quality and timing of packaging. When it comes to packaging, not only must it be high-quality and protect goods during their transportation, but it must also be delivered on time so that there aren’t any delays.

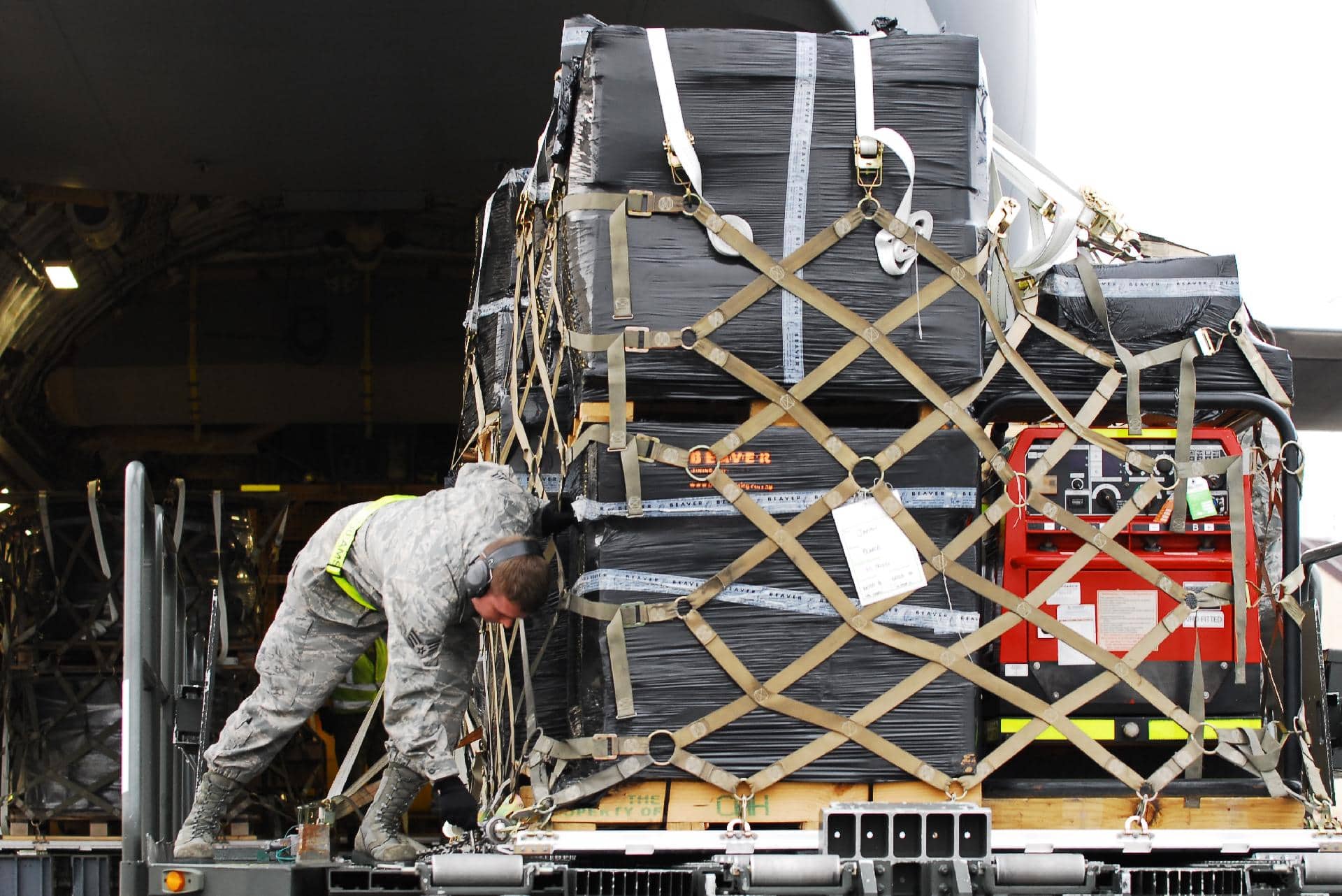

Products could be damaged, and their quality could go down if shipped as-is. A cardboard or wooden crate is used to protect the product from getting damaged or it’s quality down. The vibrations and falls that can cause Packaging can also prevent damage to the packaging. Packaging can also keep mold and rot from humidity away from the goods. If you write the name of what’s inside, how much, when it’s made, and how many boxes it has, it will be easier to tell them apart from each other. A cardboard box can make it easier to stack a cart and move things hard to carry. Packaging is also a good way to keep the quality of the food when it’s being stored.

Types of packaging for safe travel in logistics

Individual packaging, inner packaging, and outer packaging are three types of packaging based on what they are used for and how they are used.

The Individual Packaging

Individual packaging is packaging for only one thing. As an example, each piece of candy gets its own package. Water, humidity, light, and heat are all things that can damage a product if they get into it.

Inner Packaging

Inner packaging is used to put different products together in a bag. For example, this is a bag with many different kinds of candy in it. To increase sales, it is important to design an inner package that shows the product’s appeal and makes people want to buy it. This is called “inner packaging.”

Outer Packaging

This is the part of the biggest package, like a cardboard box or wooden crate. The main goal is to keep the product clean and safe.

Coordination and implementation of packaging logistics

Companies must coordinate packaging logistics with both warehouse and transportation logistics, as well as with other logistics in the area. All three areas have one thing in common: They link making things and selling them (see also Distribution Center). Packaging logistics is in charge of controlling, organizing, and improving how a company packs its products. Thus, packaging logistics ensure that the interests of storage and transportation logistics are coordinated. It also needs to develop the best solution with the packaging manufacturer so that both sides are happy.

If logistics is thought of as a field of work that plans, implements, and controls the corresponding processes and structures. Packaging is thought of as a field of work that protects, secures. It advertises products and informs and advertises; then, packaging logistics encompasses a wide range of optimization from production to the end-user.

From the point of view of the company

The packaging process is the most important part of picking, packing, and preparing for shipping. Efficient packaging logistics save money by keeping the time to pack and unpack things as short as possible. Packaging logistics also affects storage costs by figuring out how much space is needed and then choosing the right type of packaging for that space. This makes the most efficient space possible (see also storage capacity). As a whole, it is possible to think about a packaging system that goes so far as to reduce transportation volume, for example, by using less space-consuming packaging, like boxes that fit in a small space.

Thus, packaging logistics can save money and help the environment along the value chain, so it is important to use it. The following example shows how all of the different parts of packaging logistics (intralogistics, logistics, environment, and marketing) come together in a single solution.

Common types of packaging materials

Packaging is the outside cover of a product, like a box or a bag. Is it the item’s wrapper, a box, or something else that keeps it safe? Packaging can be broken down into these general groups:

- Plastics

- Paper and cardboard

- Mixed plastic and paper

- Metal

- Other types of packaging

Two main things happen when packaging is used: it protects things and helps people find things. It protects the item from damage, deterioration, theft, or tampering with it or taking it. Proper packaging makes sure that things like extreme temperatures, moisture, light, and so on don’t affect the contents of the packages inside. This is especially true when it comes to food.

It also tries to sell the product to the person who uses it or buys it. If a package is easy to use for the customer, it should work well. They should be easy to open and close and be able to dispense the product.

A well-packaged product is more likely to be safe from damage, theft, and spoilage. Items that have been well-packaged made it easy to store and find them. This is how things have changed in the packaging business over time: Disposable, recyclable, and reusable packaging for products are now available for many products in the world today.

Packaging logistics and sustainability

Environmental issues have become a big deal for people in logistics and even more so for people who work with packaging. Multi-component packaging, the air in the packages, and plastic in the oceans are some things that packaging logistics must come up with ways to deal with in this area. End customers are becoming more demanding, and the EU ban on plastics hasn’t been implemented yet. A new packaging law is also in the works. The directive proposal for recycling quotas DIN NA 115 CEN/TC 261 considers these things.

Disposable Packaging Materials

Disposable packaging materials are usually only used once, and then they are thrown away after that. Foam materials and certain types of plastics used for packaging things are two examples. Unfortunately, these end up in incinerators or landfills, which is bad for the environment because they burn things up or put things away.

Besides causing damage to the environment, if these items aren’t thrown away properly, they can harm flora and fauna in the area. As a result, most businesses use packaging that can be recycled or reused instead of something new.

The Recyclable Packaging Materials

Recyclable packaging can do many different things with some materials before they have to be thrown away. Recyclable materials are materials that we can use again and again and again. Most of the time, recyclable packaging materials are collected and sorted before being recycled. The material turned into something else can be made into packaging material or another thing.

In this way, an item that we would have thrown away as waste is reused and turned into something else or even the same thing. In this way, recyclable packaging materials are used many times before they are finally thrown away and thrown away safely.

It’s also common to use materials that we can break down. These are materials that break down quickly when exposed to the elements of nature. Plastic wraps, shrink wraps, straps, cartons, and other packaging materials that we can recycle can be used again.

Reusable Packaging Materials

Packaging logistics can use reusable packaging materials again and again without a lot of work. People often use these materials because they are durable and easy to keep clean. We can also do minor repairs to them within logistics to make them ready for use again.

In most cases, when packaging materials can be reused, the customer sends them back to the manufacturer through a third party People who work in the automobile, electronics, and beverage industries often use packaging materials that can be reused.

Current trends in packaging and logistics

Organizations are paying more attention to how packaging and packing materials are used.

Organizations have been able to meet these goals thanks to new ideas in packaging and packaging. They also try to cut down on the materials, use smart packaging, reuse or recycle materials, and make space-saving designs.

About Booker Transportation

Booker Trans is 100% Owner Operator. It is our belief that an Independent Owner is the best way to get a customers freight delivered timely and safely. Booker is a leading Refrigerated Carrier providing the best lease options in the industry for today’s Owner Operators. Monthly and Yearly Awards, Longevity Bonuses, and the Free tires for Life of Lease Program, are just a few examples of what Booker Trans offers the Owner Operator. Booker Trans has built it’s success upon working partnerships with Customers, as well as Agency Relationships built over the last 20 years. Those same relationships are what makes consistent year round freight possible.

Are you interested in becoming an owner operator driver or getting into the logistics industry?

Let’s connect!

Navigating the Highways of Change

04/18/2024

Owner Operators should be prepared for Cellular Service outages!

03/06/2024